SOLAR

NO OTHER ROBOTS WORK MORE IN SOLAR

LCRs go beyond cutting vegetation to prevent shading. They detect fire risks and generation issues that drones can’t, helping O&M run smoothly. By combining Mow, Tow, Know™ in one machine, LCRs deliver an unmatched ROI for utility-scale solar.

Boost Site Performance

Reduce Labor Costs

Improve Site Safety

Increase Transparency

Under management in utility scale solar

Actionable failures detected (generation losses, fire risks, security risks, civil and environmental issues)

SOLAR MOW

PROVEN IN THE FIELD

Solar fields are not controlled environments. They see heavy rains, lightning storms, hail and intense heat and cold. They have dense vegetation and challenging terrain. LCRs are engineered to mow in these difficult conditions.

Mowing in a thunderstorm

Mowing under fixed panels

Mowing tall vegetation

Mowing a flooded row

SOLAR KNOW

METHODICAL MONITORING, SMOOTHER OPERATIONS.

The same LCR that manages vegetation is trained to detect myriad mechanical, electrical, thermal, civil and security failures across your site.

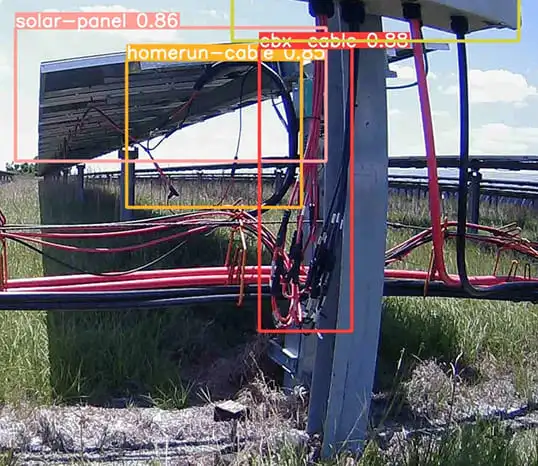

Recognize Solar Infrastructure

AI detectors trained to identify the many different objects on a solar site

Detect Generation Losses

Turn production losses into gains

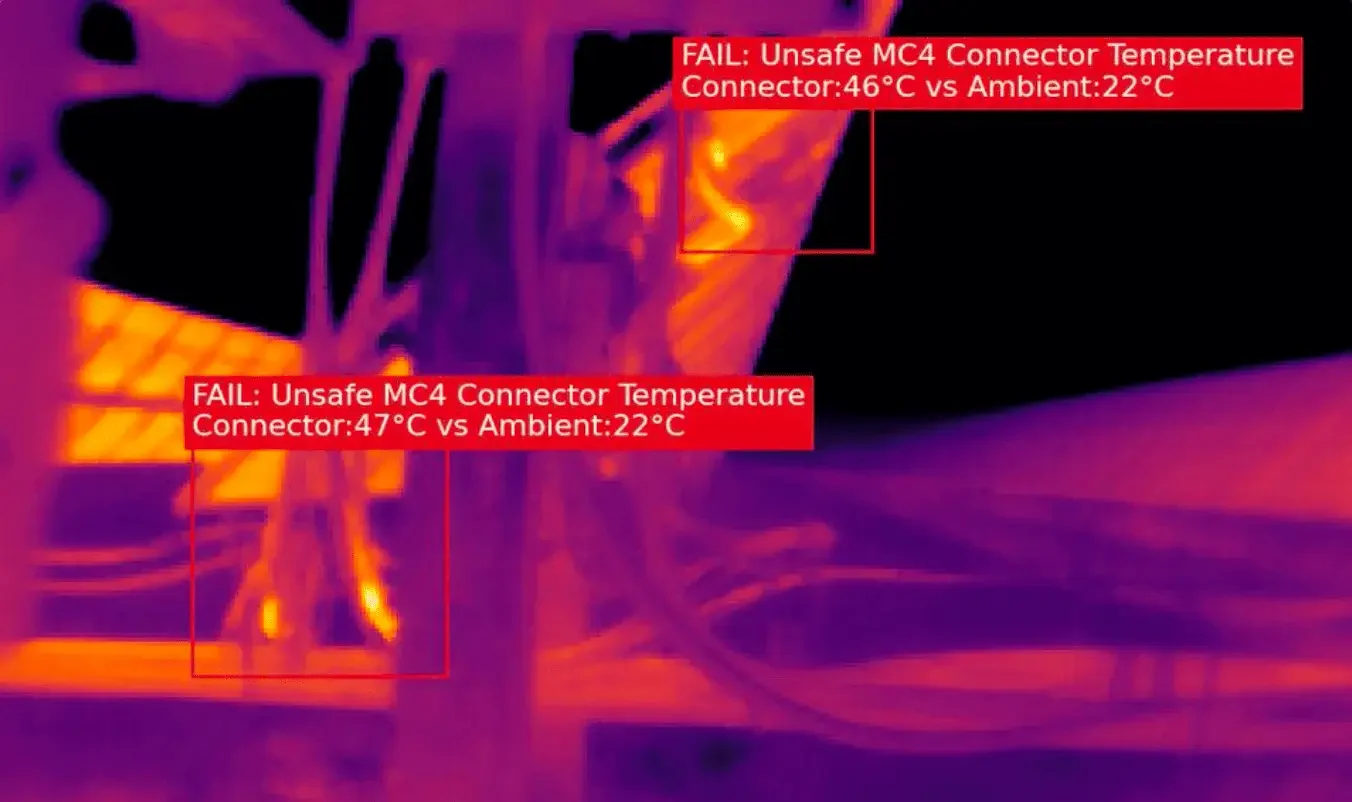

Detect Fire Risks

Solve problems before they escalate

SOLAR TOW

Cut EPC Costs with Autonomous Towing

Reduce crew size

Lower equipment costs

Keep projects on schedule